Automation can be an intimidating subject.

Relays, switches, transmitters, panels, cables, PROFINET, Modbus, HMIs, PLCs

PLC-Who? And industry standards? Don't get me started.

Let's leave this subject to the "Sparkies" - Right?

But, let's rewind.

The reality is that automation is the future, and the future is now. Thanks in part to system integration, automation has become common place for industry.

However, knowing which processes to automate, and when to automate, is key to your future success.

Automation is a long-term commitment that will positively impact business for years. Time invested up front results in a better solution

We all know that competence is power - and well, if getting into the automation world is your goal then it is crucial to get familiar with the basics.

Say no more, here is a break-down of some of the basic terms you need to learn to begin your automation mastering process.

PLC and HMI

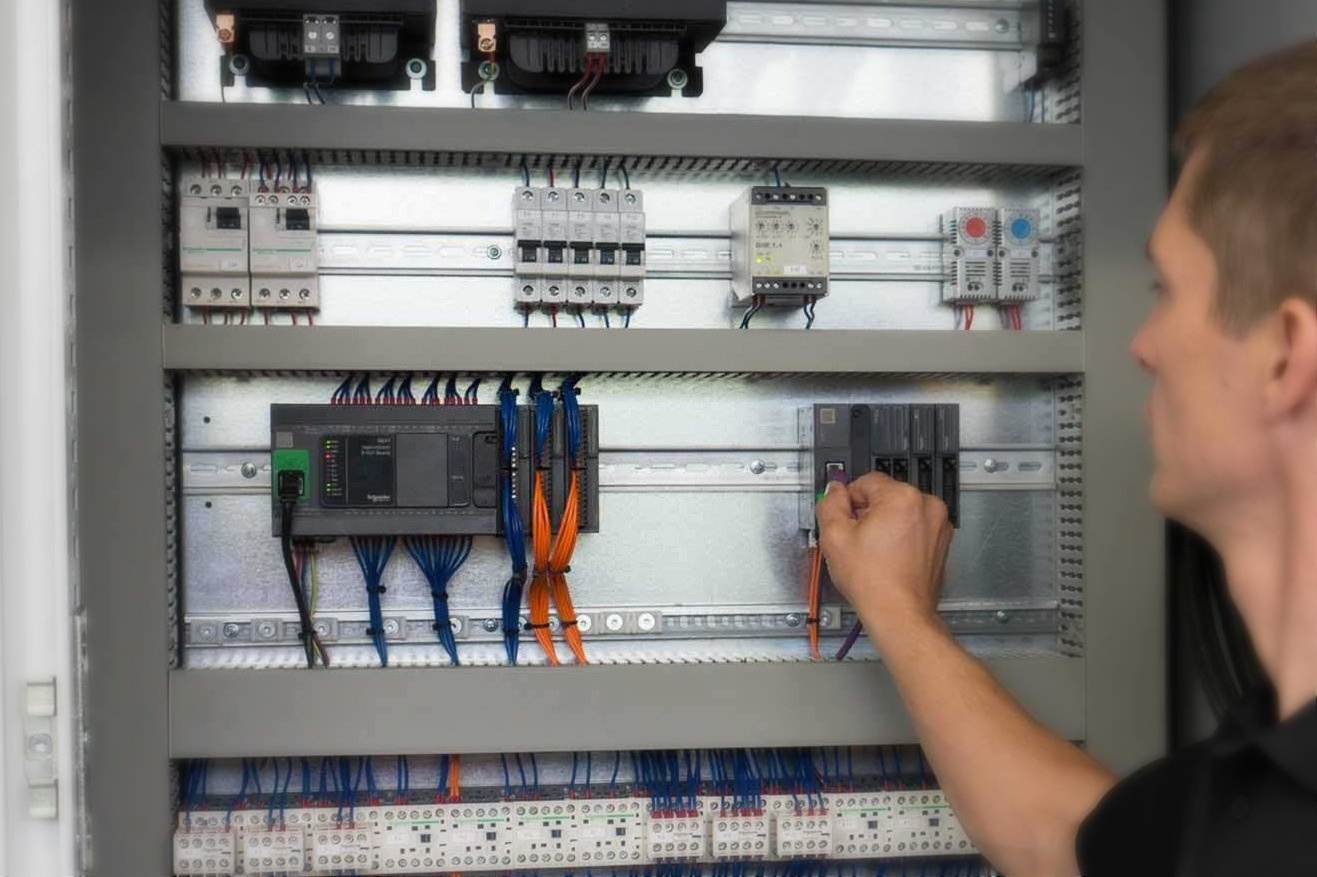

At the heart of an automated control system is the Programmable Logic Controller (PLC). The PLC is the most vital component in every controls and monitoring system.

The PLC receives information from connected sensors or input devices, processes the data, and triggers outputs based on pre-programmed parameters.

Depending on the inputs and outputs, a PLC can monitor and record run-time data such as machine productivity or operating temperature, automatically start and stop processes, generate alarms if a machine malfunctions, and more.

Via Input/Output (also referred as I/O) modules, PLCs establish a physical connection with the system's components.

Poor choice in PLC selection and/or programming can be the difference between smooth and efficient operations or constant headaches in troubleshooting and debugging. It can also drain a projects budget.

PLC systems can integrate with other devices and work with many industrial network protocols and hardware layers (PROFIBUS, PROFINET, Ethernet I/P, Modbus, RS-232, RS-485, and others).

The Human Machine Interface (HMI) has come a long way from being a simple monitor on the wall or panel door.

HMI’s give Operators the ability to monitor and interact with the controls system. But not all HMI’s are created equal, and they are surely not one size fits all.

The software platform for your HMI’s are determined by your system’s needs.

Its important to recognize that custom programming allows the HMI to be seamlessly integrated into the controls process.

Instrumentation and Control

Instrumentation engineering focuses on control processes that use sensors as an input.

Feedback from such sensors can be used throughout the system operation process. The sensors can measure and monitor parameters such as specific machine outputs, the efficiency of systems and, most importantly, safety parameters.

They also play an extremely important role in the monitoring and recording of quality data to ensure the safety and reliability of the system.

The ultimate goal of instrumentation engineering is to ensure that control machinery and processes are operating to achieve maximum productivity in an optimally efficient, safe and reliable manner.

Instrumentation engineers may be responsible for any part of the control process' lifecycle. Related tasks include planning, design, development, and installation of a new process. They could also monitor, maintain and manage teams responsible for control systems already in place

Control Panel Design

Automation cannot operate and be properly maintained without first developing a suitable control panel design.

Every control system needs a control panel design, and that includes drawings — electrical schematics, assembly and layouts.

Building and wiring a panel without the design represented in a schematic is like mopping the floor without sweeping first; when complete, it's just a bad job.

Drawings are always required, just as installing wire numbers, on all wiring in an industrial automation control panel, is always required.

Its important to recognized that the designs may follow standards such as found in the NFPA 79: Electrical Standard for Industrial Machinery, UL508A, among others.

Placing importance on requirements as specified in the industry standards is crucial to achieve optimal safety.

Whats next? Are you still overwhelmed?

Great, thanks for the 101 - Where do we start?

We understand that your Operators are probably not Controls Engineers, and that complicated programs will hinder the efficiency of the controls system rather than assist your Operators in effectively performing their jobs.

At StoneWall our team facilitates innovation by providing:

-

Expert assistance in selecting the most cost effective PLC so that our clients don’t needlessly blow their budget

-

PLC and HMI programming services so that the client spends more time focused on growing their business than troubleshooting glitches

-

Custom programming to allow the HMI to be seamlessly integrated into the controls process

-

Full range of Instrumentation and Control Support

-

Expertise designing systems and select the proper controls instrumentation.

-

Assistance designing control panels, while holding compliance to industry standards including NFPA and UL

-

Control panel design includes developing associated drawings — electrical schematics, assembly and layouts

ABOUT PES

PES will always be dedicated to providing top-notch customer service to meet our industry demands. We set ourselves apart with our consistency and timely turnarounds. We are always committed to being responsive to our clients, KEEPING OUR PROMISES, making delivery schedules, and standing by our designs!

From concept, design, and engineering, to project management and integrity services. We are your gateway to your journey's engineering endeavors. Including oil & gas, hemp & CBD, and food industries.

Providing services focusing on Facilities Engineering, Turn-Key Solutions, Downhole Tools, Structural Engineering, Civil Engineering, Commercial Construction Design and Engineering, Direct Lithium Extraction, and Drafting & Design.

References

Control panel design starts with the basics - https://www.controldesign.com/articles/2016/control-panel-design-starts-with-the-basics/

Industrial Control Panel Design Guide: Schematics, Standards, Design Considerations & More - https://www.mpofcinci.com/blog/industrial-control-panel-design-guide/

System Integrator’s Inside Tip: When To Automate - https://epicindustrialautomation.com/blog/system-integrators-tip

What is an Instrumentation Engineer? - https://www.getreskilled.com/what-is-an-instrumentation-engineer/