Equipment Certification Standards in the Oil and Gas Industry

The oil and gas industry, known for its complex and high-risk operations, demands stringent adherence to various equipment certification standards....

2 min read

Stonewall Engineering

Apr 16, 2020

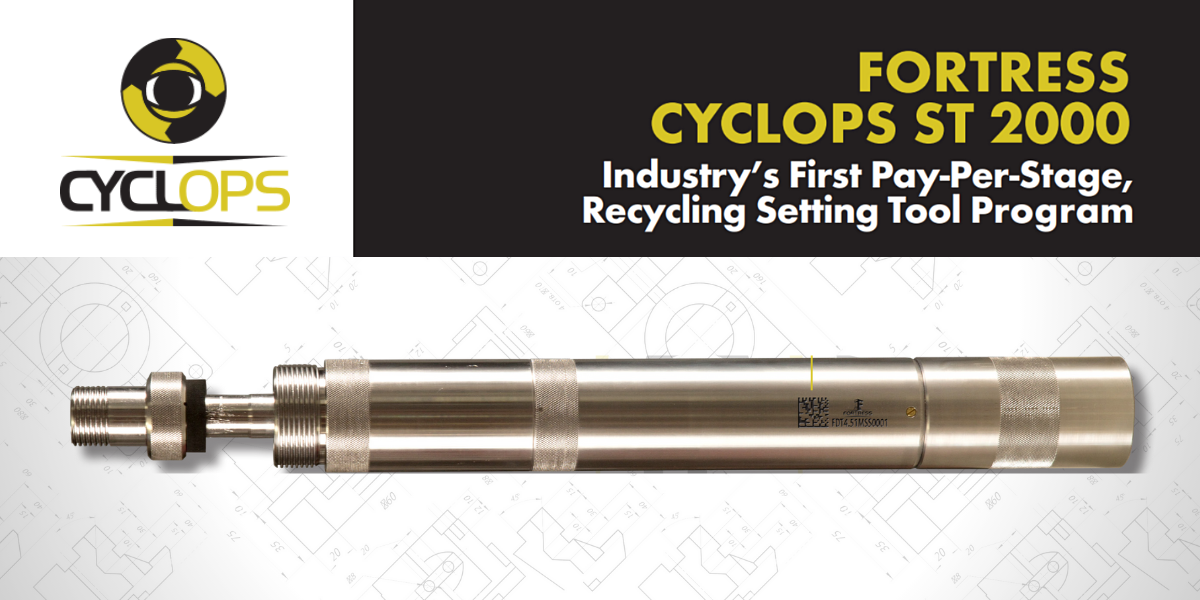

Fortress Downhole Tools is excited to bring to market the industry’s first Pay-Per-Stage, recycling setting tool program.

Keep reading to discover all the benefits of this incredible technology.

The oil and gas industry, known for its complex and high-risk operations, demands stringent adherence to various equipment certification standards....

In the dynamic world of engineering, where precision and performance are non-negotiable, Finite Element Analysis (FEA) stands as a game-changer. At...

As every engineer in the field knows, when it comes to standards, API is our go-to when focusing on oil and gas industry operations and procedures -...

The Cyclops ST 2000, Fortress Setting Tool is a gas operated, oil-free setting tool, designed to replace the standard Baker-style wireline setting tool and also disposable tools.

From concept, design, to engineering, StoneWall has operated as the gateway to the Cyclops ST 200 engineering design journey.

patent-pending tooL

This patent-pending tool is 50-60% cheaper than other disposable tools, and is specifically designed to reduce downtime and increase cycling of operations, hence deemed: “Cycl-ops”.

proprietary dampening stage design

The design also includes a proprietary dampening stage and dual bleed off in order to safely and efficiently set any downhole tool that is designed to be run on the Baker 20 setting tool or equivalent.

coupled with Fortress’s Cyclops Efficiency Program

This game-changing tool coupled with Fortress’s Cyclops Efficiency Program or CEP can improve your cash flow by giving you instant ownership type accessibility in a rental tool system.

No supply chain headaches.

Incredible Benefits

The simplicity, efficiency, versatility and compact size of the Cyclops is what separates itself from all other setting tools on the market - enabling cost savings and safety benefits while operating as a reliable tool.

Cost Savings

All Inclusive Price Per Stage

The Cyclops comes with in all inclusive "Price Per Stage" model.

This includes the Setting Tool, Rebuild Kit, iFortress, and Inspections.

Direct Replacement of Disposables

It also comes with direct replacement of disposables which is 50% lower the cost of other disposable setting tools.

With the Cyclops, operators can continue running the same gun system and the number of guns.

Reduced Risk of NPT

The Cyclops also reduces the risk of NPT with its pressure balanced design and eliminates the need for pressure induced pre-set plugs.

Safety

Self Bleeding Design

The Cyclops' self-bleeding design has a 100% success rate of bleed off downhole.

It also contains redundant bleed areas along with a "Tattletail" feature that visually confirms bleed off at the surface.

Efficiency and Reliability

The Cyclops has a simple design consisting of only 5 total tool components and 5 HiVis O-rings.

This allows for a quick redress. The average rebuild time on location is seven minutes.

Fortress also provides on-site training at no additional cost which provides even more efficiency.

Compatibility

The Cyclops accepts industry standard energetics and WLAK's.

It can also set both composite and dissolvable plugs with virtually no limitations.

Specifications For The Cyclops ST 2000

Model: ST2000

Length – 39.59”

Weight – 73 lbs

Shear Force – 60,000 lbs

Stroke Length – 10.00”

Advantages

Pressure Balanced

No Hydrostatic Limitations

Oil-Free Design / Self Bleeding

Proprietary Dampening Stage & Dual Bleed Off

Average 7 min Rebuild Time

(5) Tool Components

Only Requires (5) O-Rings

On-Site Field Training / Seamless Integration

iFortress Run Data Tracking

Want to learn more?

Add Fortress’s fully customizable iFortress tool and data tracking app and you now have all critical run data at your fingertips.

ABOUT FORTRESS

Our product offering is further enhanced by providing our clients with our patent pending “e-inventory” supply chain management system. With over 100 years of energy sector experience and a passion for “customer service” we strive to always do what’s best for our customers.

ABOUT STONEWALL ENGINEERING

Providing services focusing in Facilities Engineering, Turn-Key Solutions, Hemp Facilities, Food Plant Engineering, Manufacturing, Engineering Services and Drafting & Design.