Engineering has always been a fairly "technological" space.

But as technology is continuing to evolve at a rapid pace, engineers are being forced to evolve themselves.

No industry, much like all species of this world, is immune to adaptation.

Sticking with the old, outdated ways of doing things will leave you left in the dust and thus decomposing to just another bankrupt, fossil fuel.

So, what are some of the latest technologies that the engineering world should be aware of, and rapidly embrace if they want to stay afloat in this rapidly shifting space?

Keep reading to learn more about the best 10 ways to equip your mind and business for sustainable growth in the engineering industry and business space.

2. PRODUCT DATA MANAGEMENT SYSTEMS

5. UTILIZING THE LATEST MANUFACTURING TECHNOLOGY

1. CAD in the Cloud

We have written about CAD in the Cloud before, but its relevance and importance are worth restating. Cloud based systems are necessary in every business today.

If you are still utilizing the large super computer in your office for your CAM and CAD work, please know that isn't necessary any longer.

Leveraging offsite databases not only allows for better efficiency and power management, it also centralizing all your data in one place.

So all of your engineers can have the same designs anywhere, at anytime, on any device.

As an up to date Engineering consulting company, the one thing you don't want diversified are your file revisions and access to them.

Centralization is the key to future success when it comes to your data management.

2. Product Data Management Systems

First off, if you are not aware of what PDM's are or what they do, let's start there first.

Product data management (PDM) is the use of software to manage product data and process-related information in a single, central system.

This information includes computer-aided design (CAD) data, models, parts information, manufacturing instructions, requirements, notes and documents.

If you haven't looked into the latest and greatest PDM software available or you have but are just confused on how to properly use it, look into buying better products or seek a PDM expert to remove your bottlenecks.

3. Deep Learning and AI

If there is anything you want to be paying attention to in 2019, it is how to better utilize machine learning, AI, and the growing set of AI tools reshaping industries.

While humans may be able to reason much better than computers, we cannot learn and replicate systems with such ease as AI and deep learning systems.

No matter what type of engineering you are an expert in, whether it is civil engineering, mechanical engineering, electrical engineering, etc., learning how AI is shifting the game up could keep you on the bleeding edge of business development coming into the new year.

4. Digital Marketing

Long gone are the billboard marketing days and solely using printed marketing means.

Not just because they are ineffective, but because unless you are a maritime or injury attorney, there simply just isn't enough billboard real estate to go around.

Your best bet is looking for an digital marketing and sales expert to help get you moving in the right direction and get your company in front of the eyes of more qualified leads of your industry. Digital marketing can help in defining ways on how to attract more potential customers and generate leads (inbound marketing) and how to start earning more qualified traffic to your website (Search Engine Optimization aka SEO).

The marketing game has shifted, and if you want to grow your business, your thoughts on how to market your brand and business are going to have to shift as well.

5. The uprising of digital transformation and Industry 4.0

Along any engineer’s journey of seeking perfection, the one thing you must give attention to is operating as lean as possible.

And, of course, it is impossible to lean up your operations without paying loads of attention to your process.

And even though your daily operating systems are of extreme importance, engineers that aren’t up-to-date on the latest manufacturing technology, will soon be left behind.

While there are many advanced technologies in the manufacturing world, the most intuitive engineers would be wise to pay attention to multipurpose technologies such as machine-learning algorithms that happen to be capable of automating processes like feedback, quoting as well as design for manufacturability. As technology continues to get "smarter", engineers continue to find ways of in automating their equipment (or machine retrofitting) and dive into the age of digital transformation.

But what is this Industry 4.0 thing?

The industry of tomorrow, Industry 4.0 is a computer-driven manufacturing system that makes use of the internet for increased efficiency and consistency in production processes by using sensors to collect data on machine performance while simultaneously integrating all stakeholders into one centralized network where they can see real time updates from various machines within their plants or regions across company lines - this way there are never any surprises!

It's no surprise that Industry 4.0 is all about doing things differently, and the manufacturing industry has taken notice with new innovations in automation to meet changing market demand--including cyber-physical systems like Industrial Internet of Things (IoT), as well as cloud computing.

These technologies can help drive growth goals for manufacturers who are willing to adopt an innovation mindset by embracing change rather than maintaining their status quo position against today’s demanding customer base.

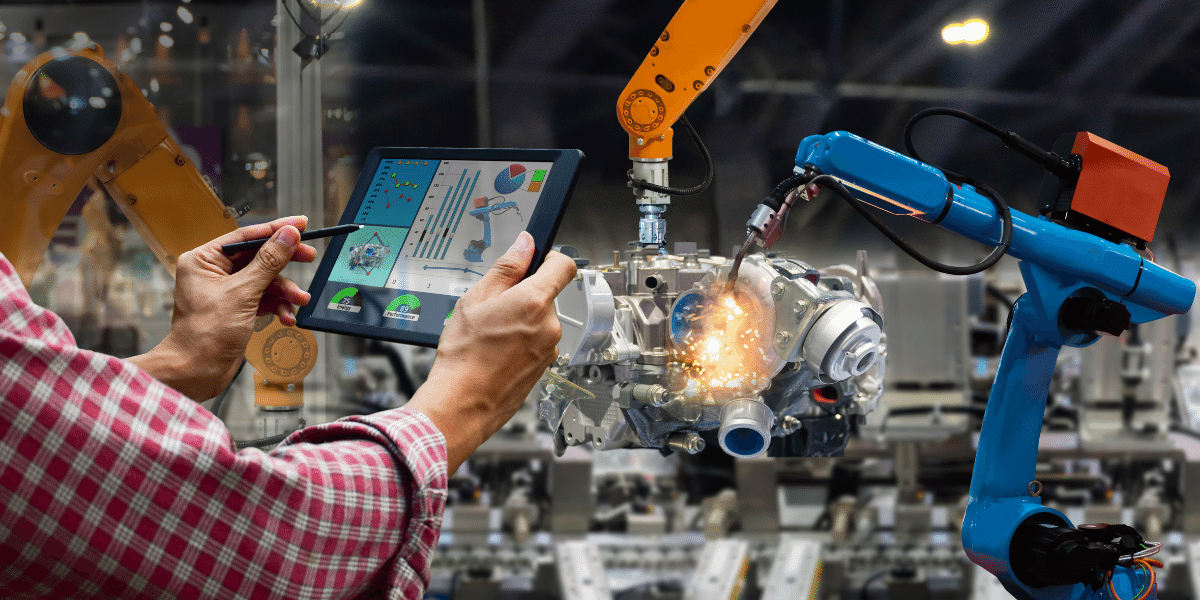

6. Robotics

Of course, whenever you hear the words “modern”, “technology” or "industry 4.0" we often think about robots.

And while it may just seem like a cool concept, many companies are making huge strides in the oilfield and engineering world by designing and utilizing robots (fancy word for automated machine) to complete jobs within dangerous environments or extreme conditions.

Not only is utilizing robots for these types of jobs much safer than sending humans in, but they are way more efficient.

Robotic automation may help manufacturers decrease costs and improve the effectiveness of their operations. For example: 3D-printing can help manufactures and engineers achieve a lean manufacturing process due to their unique qualities. Another example: Robots can be used as retrofit solutions of existing equipment for medium and large volume production runs as demand rises.

In the manufacturing industry, robotics are known as means of "flexible automation" - a method of automation that allows it to quickly respond to production changes. To run, personnel need to program the computerized systems to control the machines. Alternatively, they can use Human Machine Interfaces (HMIs).

7. IT Infrastructure

One thing engineers are really good with is diving into the specifics of how a process currently works, then figuring out what could make it better or faster.

Yet, there is always a piece of the puzzle that if left unchecked, it could drastically slow down the entire process. And that, of course, is the company's IT infrastructure.

First off, the best thing that you can do is outsource your IT to a worthy managed service provider.

If anything, this will allow you to continue to do what you do best and leave the technology side of things to someone else which results in total production optimization.

Second, once you have outsourced the infrastructure, look for better software and programs that will drive more production output on your end.

There are plenty of infrastructure solutions on the market that will not only help relieve the headache of IT, but will ensure that you are operating smoothly with the technology assistance that is being provided.

8. Automation and SCADA

This one doesn’t take a genius to comprehend:

If you or your company is repeating simple tasks or certain jobs can be programmed, then you must automate, automate, automate.

Whether its integrated production optimization, data infrastructure and business analytics, or utilizing SCADA, if the process can be done faster and more efficiently with automation, don’t hesitate to implement the necessary applications to make it happen.

9. Communication systems

Want to know what the greatest cost to most businesses is?

It's communication.

In one way or another, communication, if left ignored, will somehow find a way to stalemate most business growth or efficiency.

Owners and employees must remain diligent in building and fostering the right relationships within and outside of the company.

![]()

Investing in your internal and external communication systems and processes will not only prevent your business from going belly up, but it will drastically increase your chances of a smooth scaling process.

10. Leadership Systems

And what is great communication without effective leadership?

Most businesses often speak about, yet totally overlook the necessity of having an effective leadership system.

As a business owner, or an indispensable executive, you are responsible for making it necessary for all of your team members to seek to improve the culture at your workplace.

This culture should be heavily weighted in not only a strong work ethic, but of increasing competency.

Yet, before you can push the importance of this down to your people, remember to make sure to focus on yourself and look to improve your own effectiveness and self-discipline.

Related Articles

Energy Engineering: Powering the Future - Explore the world of energy engineering: its importance, skills required, facts, and its crucial role in climate change and sustainable development.

ABOUT PES

PES will always be dedicated to providing top-notch customer service to meet our industry demands. We set ourselves apart with our consistency and timely turnarounds. We are always committed to being responsive to our clients, KEEPING OUR PROMISES, making delivery schedules, and standing by our designs!

From concept, design, and engineering, to project management and integrity services. We are your gateway to your journey's engineering endeavors. Including oil & gas, hemp & CBD, and food industries.

Providing services focusing on Facilities Engineering, Turn-Key Solutions, Downhole Tools, Structural Engineering, Civil Engineering, Commercial Construction Design and Engineering, Direct Lithium Extraction, and Drafting & Design.